- HealthTech

Nike Launches First 3D-Printed Sports Bra for Elite Athletes

5 minute read

Nike’s breakthrough 3D-printed sports bra technology transforms athletic apparel manufacturing while delivering unprecedented performance benefits for runners

Three Key Facts

- Nike debuts FlyWeb 3D-printed sports bra for Olympic champion Faith Kipyegon’s historic 4-minute mile attempt on June 26 in Paris, marking the first high-performance 3D-printed apparel for elite athletes.

- Three years of development resulted in breakthrough TPU material technology that offers targeted support while reducing thermal burden and moisture retention compared to traditional sports bras.

- Amazon partnership expands distribution capabilities for custom-fit sports bras, leveraging extensive logistics network to reduce production costs and delivery times for mass market applications.

Introduction

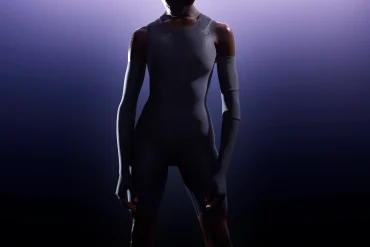

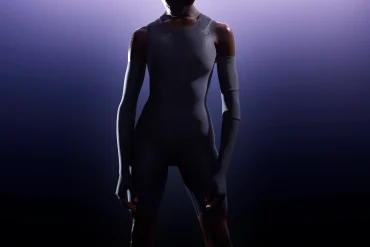

Nike launches its first 3D-printed sports bra for elite athletic performance, marking a significant advancement in how performance apparel is manufactured and designed. The FlyWeb Bra represents three years of research into materials and computational design, moving beyond traditional knitting and weaving methods to create garments from thermoplastic polyurethane (TPU).

Three-time Olympic champion Faith Kipyegon will debut the custom-made bra during her attempt to become the first woman to break the 4-minute mile. The collaboration with Amazon positions this innovation for broader market distribution, potentially transforming how consumers access personalized athletic wear.

Key Developments

Nike’s Innovation team developed FlyWeb technology specifically to address limitations in traditional sports bra design. Conventional sports bras create thermal burden and retain moisture against the body, impacting performance even in shorter events like the mile run.

The 3D-printed TPU material manages moisture more effectively than traditional textiles while providing targeted support through computationally designed surfaces with varying density. Janett Nichol, Nike VP of Innovation, explains the technical challenge: “What works on a shoe doesn’t just translate to something you wear on your body. It took years of re-engineering to make FlyWeb soft, breathable and beautiful enough for apparel.”

Kipyegon began testing the custom-made bra this spring, providing athlete feedback that informed final design adjustments. The racerback design increases range of motion while the seamless construction eliminates traditional straps and extra material that can restrict movement.

Market Impact

The sports apparel market anticipates expansion at a 6-7% compound annual growth rate through 2027, with 3D-printed products positioned to capture premium pricing segments. Nike expects cost savings from reduced waste, shorter development cycles, and localized production capabilities to enhance margins in this growing market.

Industry analysts view the development as a catalyst for broader adoption of additive manufacturing in fashion. The shift from experimental to mainstream digital manufacturing signals potential disruption of traditional supply chains and production methods across the sportswear sector.

Strategic Insights

Nike’s FlyWeb initiative builds on previous successes with 3D-printed footwear, including the Air Max 1000 and collaborations with specialists like Zellerfeld. The strategy encompasses four key pillars: mass customization, sustainability through reduced material waste, rapid prototyping for faster market response, and localized production to minimize supply chain risks.

The partnership with Amazon addresses scalability challenges by leveraging extensive distribution networks. According to The Information, this collaboration aims to make custom-fit sports bras widely available while reducing production costs and delivery times for consumers.

Decentralized manufacturing presents significant advantages in addressing post-pandemic supply chain vulnerabilities. The approach enables rapid response to market trends and athlete feedback while reducing dependence on traditional manufacturing centers.

Expert Opinions and Data

Kipyegon’s reaction to testing the prototype highlights the performance benefits: “I’ve never worn something like this in my life. I love it.” The custom-made design addresses her specific body measurements and performance requirements for the record attempt.

Nichol emphasizes the unique user experience: “You can actually feel the air on your chest. Most women have never experienced that while running. We don’t even think about it because it’s just not something we’ve ever expected to feel.” The technology creates responsive athletic support without traditional construction methods.

Industry observers praise Nike’s approach for pushing boundaries in product design and manufacturing. Nichol describes the broader implications: “This is a true unlock, not just for bras but for how we design and build high-performance apparel going forward.”

Conclusion

Nike’s FlyWeb Bra demonstrates the transition of 3D printing technology from experimental applications to mainstream performance sportswear. The combination of athlete-driven development, advanced materials science, and strategic distribution partnerships positions the innovation for significant market impact.

The initiative aligns with Nike’s broader commitment to sustainability and innovation while addressing real performance limitations in traditional athletic apparel. Digital transformation in sportswear manufacturing now moves from prototype to practical application, setting new standards for how performance products are designed and delivered to athletes and consumers.